- 您现在的位置:买卖IC网 > Sheet目录187 > 4310R-101-222 (Bourns Inc.)RES ARRAY 2.2K OHM 9 RES 10-SIP

Features

■ RoHS compliant* versions available (see

How to Order “Termination” option)

■ Now available with improved tolerance

to ±0.5 %

–82 0 –10

431

C11

3 2

R

11

■ Low pro?le provides compatibility with

DIPs

■ Compatible with automatic insertion

equipment

■ Superior package integrity

4300R Series - Thick Film Molded SIPs

Product Characteristics

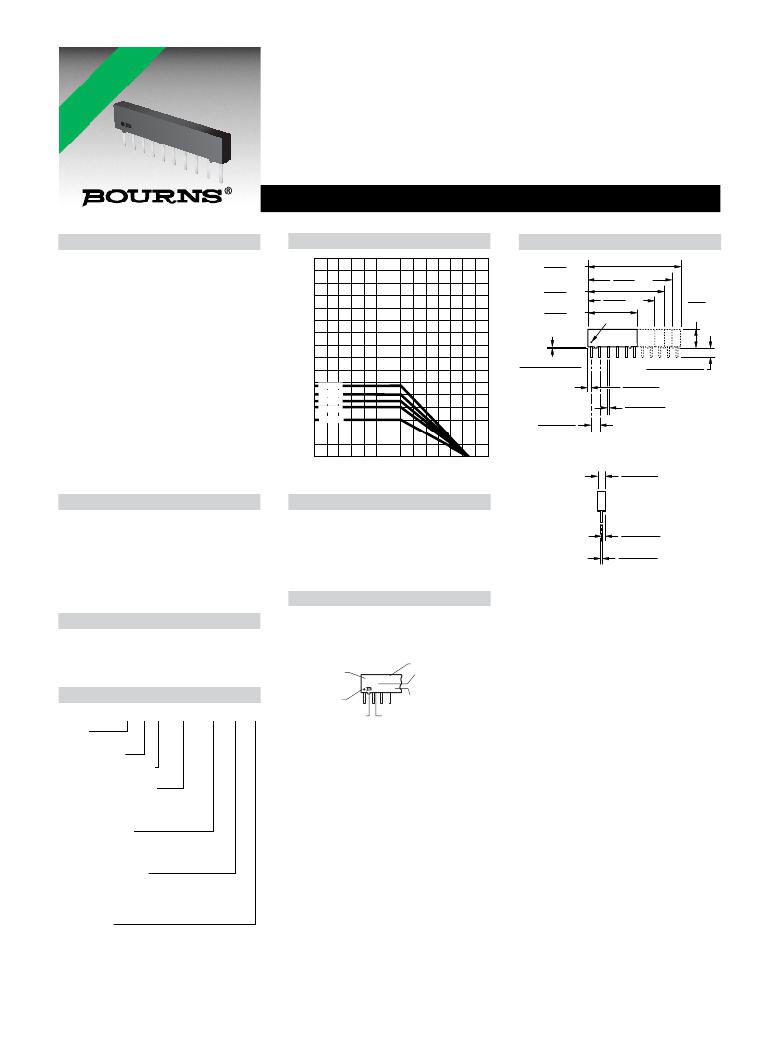

Package Power Temp. Derating Curve

Product Dimensions

MAX.

MAX.

MAX.

MAX.

Resistance Range

.................... 10 ohms to 10 megohms

Maximum Operating Voltage .........100 V

Temperature Coef?cient of Resistance

50 Ω to 2.2 megohms.....±100 ppm/°C

below 50 Ω .....................±250 ppm/°C

above 2.2 megohms.......±250 ppm/°C

TCR Tracking.........................50 ppm/°C

3.50

3.00

2.50

27.53

(1.084)

22.45

(.884)

14.83 MAX.

(.584)

24.99

(.984)

19.92

(.784)

PIN #1 REF.

4.95

(.195)

MAX.

maximum; equal values

Resistor Tolerance ............... See circuits

Operating Temperature

................................-55 °C to +125 °C

Power Rating ................... Derate to zero

power from + 70 °C to + 125 °C

Insulation Resistance

................ 10,000 megohms minimum

Dielectric Withstanding Voltage

2.00

1.50

1.00

.50

4311R

4310R

4309R

4308R

4306R

.407 + .102/ - .000

(.016 + .004/ - 000)

2.54 .07

(.100 .003*)

TYP.

NON-ACCUM.

1.02

(.040

.483

(.020

3.43 + .38/ - .25

(.135 + .015/ - .010)

.12

.005)

.050

TYP.

.002)

...........................................200 VRMS

Lead Solderability .....Meet requirements

0

25

70 125

AMBIENT TEMPERATURE ( ° C )

2.16 .10

of MIL-STD-202 Method 208

Environmental Characteristics

TESTS PER MIL-STD-202 ...... ?R MAX.

Package Power Rating at 70 °C

4306R .....................................0.75 watts

(.085 .004)

Short Time Overload..................±0.25 %

Load Life ....................................±1.00 %

Moisture Resistance ..................±0.50 %

Resistance to Soldering Heat

...............................................±0.25 %

4308R .....................................1.00 watts

4309R .....................................1.13 watts

4310R .....................................1.25 watts

4311R .....................................1.38 watts

1.02

(.0425

.254

(.010

.05

.002)

.050

.002)

Terminal Strength ......................±0.25 %

Thermal Shock ..........................±0.25 %

Physical Characteristics

Flammability ........ Conforms to UL94V-0

Lead Frame Material

Typical Part Marking

Represents total content. Layout may

vary. Marking may be truncated on

shorter versions due to size constraints.

Governing dimensions are in metric. Dimensions in parentheses

are inches and are approximate.

*Terminal centerline to centerline measurements made at point of

emergence of the lead from the body.

.........................Copper, solder coated

Body Material.................. Novolac epoxy

How To Order

PART

NUMBER

PIN ONE

INDICATOR

4310R-102

-823

CYYWW

CIRCUIT

RESISTANCE

CODE

DATE CODE

43 06 R - 101 - 222 __ __

Model

(43 = Molded SIP)

MANUFACTURER'S

TRADEMARK

COUNTRY OF MANUFACTURE

(C = COSTA RICA)

Number of Pins

Physical Con?guration

(R = Thick Film Low Pro?le)

Electrical Con?guration

? 101 = Bussed

? 102 = Isolated

? 104 = Dual Terminator

Resistance Code

? First 2 digits are signi?cant

? Third digit represents the

number of zeros to follow.

Resistance Tolerance

? Blank = ±2 % (see “Resistance Tolerance”

on next page for resistance range)

? F = ±1 % (100 ohms - 1 megohm)

? D = ±0.5 % (100 ohms - 1 megohm)

Terminations

? All electrical con?gurations EXCEPT 104:

LF = Tin-plated (RoHS compliant version)

? ONLY electrical con?guration 104:

L = Tin-plated (RoHS compliant version)

? Blank = Tin/Lead-plated

Consult factory for other available options.

For Standard Values Used in

Capacitors, Inductors, and Resistors,

*RoHS Directive 2002/95/EC Jan. 27, 2003 including annex and RoHS Recast 2011/65/EU June 8, 2011.

Speci?cations are subject to change without notice.

Customers should verify actual device performance in their speci?c applications.

发布紧急采购,3分钟左右您将得到回复。

相关PDF资料

4384-6

BOX PLASTIC W/GUIDES & COVER BLU

4416P-2-203

RES ARRAY 20K OHM 15 RES 16-SOIC

445W35W35M00000

CRYSTAL 35.00000 MHZ 10PF SMD

44EN14-10

SEALED AERO SWITCH

450-019

CONN BOOT STRAIN RELIEF RED

450-024

CONN BOOT STRAIN RELIEF CLEAR

45719-0008

CONN POWER EDGE 6POS VERT PCB

45AYP6C

FILTER 3-PHASE RFI SINGLE 45A

相关代理商/技术参数

4310R-101-222FLF

制造商:Bourns Inc 功能描述:Res Thick Film NET 2.2K Ohm 1% 1.25W ±100ppm/°C BUS Molded 10-Pin SIP Pin Thru-Hole

4310R-101-222LF

功能描述:电阻器网络与阵列 2.2K 10Pin 2% Bussed RoHS:否 制造商:Vishay/Thin Film 产品类型:Networks 电路类型:Divider 电阻器数量: 电阻数值:10 kOhms 容差:0.1 % 温度系数: 管脚数量:3 工作温度范围:- 55 C to + 155 C 尺寸:1.02 mm W x 3.05 mm L x 1.4 mm H 引线间隔: 端接类型:SMD/SMT 封装:Reel

4310R-101-222LF

制造商:Bourns Inc 功能描述:RESISTOR BUS RES N/W 9 2.2KOHM 2% SI 制造商:Bourns Inc 功能描述:RESISTOR, BUS RES N/W 9, 2.2KOHM, 2%, SIP

4310R101223

制造商:BOU 功能描述:SRN10B322 BOURNS NXF8B

4310R-101-223

功能描述:电阻器网络与阵列 22K 10Pin 2% Bussed RoHS:否 制造商:Vishay/Thin Film 产品类型:Networks 电路类型:Divider 电阻器数量: 电阻数值:10 kOhms 容差:0.1 % 温度系数: 管脚数量:3 工作温度范围:- 55 C to + 155 C 尺寸:1.02 mm W x 3.05 mm L x 1.4 mm H 引线间隔: 端接类型:SMD/SMT 封装:Reel

4310R-101-223LF

功能描述:电阻器网络与阵列 22K 10Pin 2% Bussed RoHS:否 制造商:Vishay/Thin Film 产品类型:Networks 电路类型:Divider 电阻器数量: 电阻数值:10 kOhms 容差:0.1 % 温度系数: 管脚数量:3 工作温度范围:- 55 C to + 155 C 尺寸:1.02 mm W x 3.05 mm L x 1.4 mm H 引线间隔: 端接类型:SMD/SMT 封装:Reel

4310R-101-223LF

制造商:Bourns Inc 功能描述:RESISTOR BUS RES N/W 9 22KOHM 2% SI 制造商:Bourns Inc 功能描述:RESISTOR, BUS RES N/W, 9, 22KOHM, 2%, SIP

4310R-101-224

功能描述:电阻器网络与阵列 220K 10Pin 2% Bussed RoHS:否 制造商:Vishay/Thin Film 产品类型:Networks 电路类型:Divider 电阻器数量: 电阻数值:10 kOhms 容差:0.1 % 温度系数: 管脚数量:3 工作温度范围:- 55 C to + 155 C 尺寸:1.02 mm W x 3.05 mm L x 1.4 mm H 引线间隔: 端接类型:SMD/SMT 封装:Reel